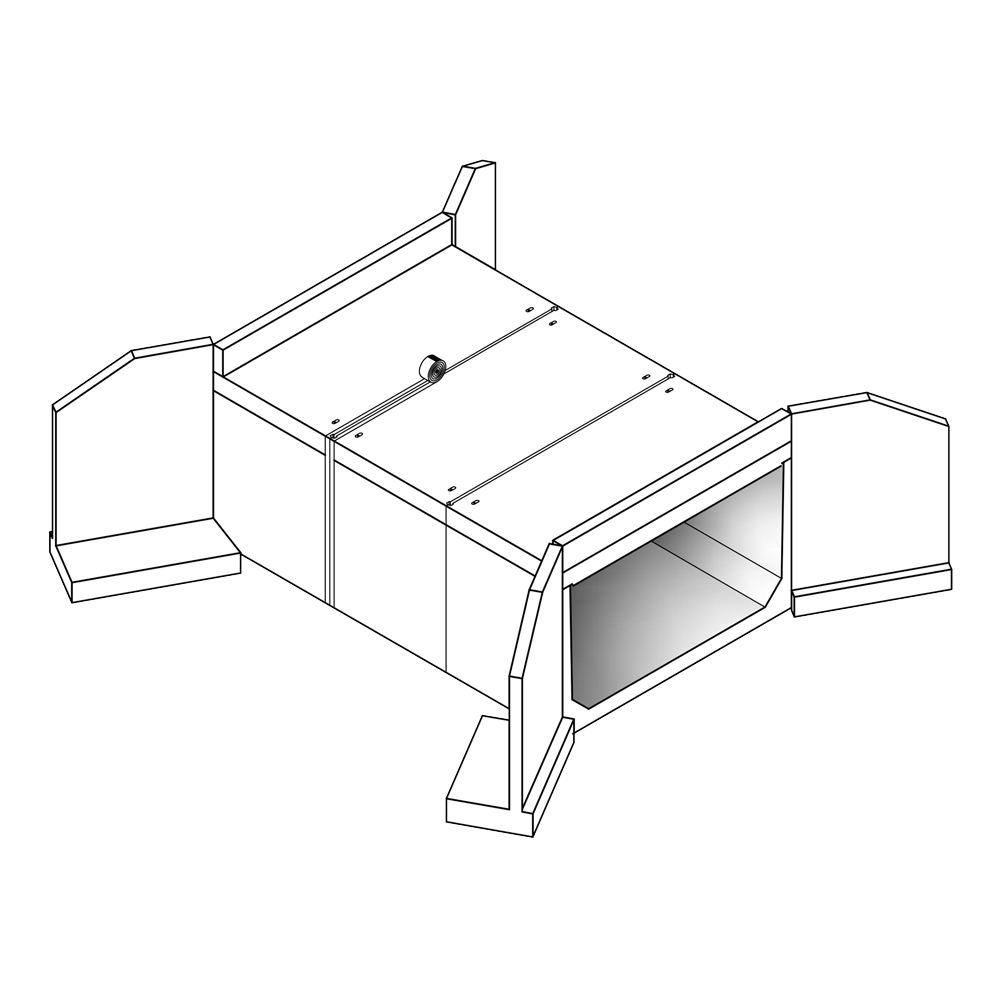

Precast Concrete

for the Pacific Northwest

We manufacture durable, reliable, ready-to-install concrete products to serve the rapidly-changing infrastructure of our region.

Office Hours

7am-4pm

Monday-Friday

Phone: 360-335-8400

Fax: 360-335-8402

Estimations: sales@cppwa.com

Will Call Hours

7am-2:30pm

Monday- Friday

Located in Southwest Washington, we produce quality precast concrete.

From roads and parking lots, tunnels and drainage trenches, our people take pride in completing projects on schedule and on budget. When you call Columbia Precast, you will speak with a friendly, knowledgeable person ready to help you complete your project safely and efficiently.

The CPP management and production team have more than 140 years of combined experience in the precast industry. We work to produce the highest quality precast products available.