Box Culverts / Bridges

| Box Culverts | Spec Sheets |

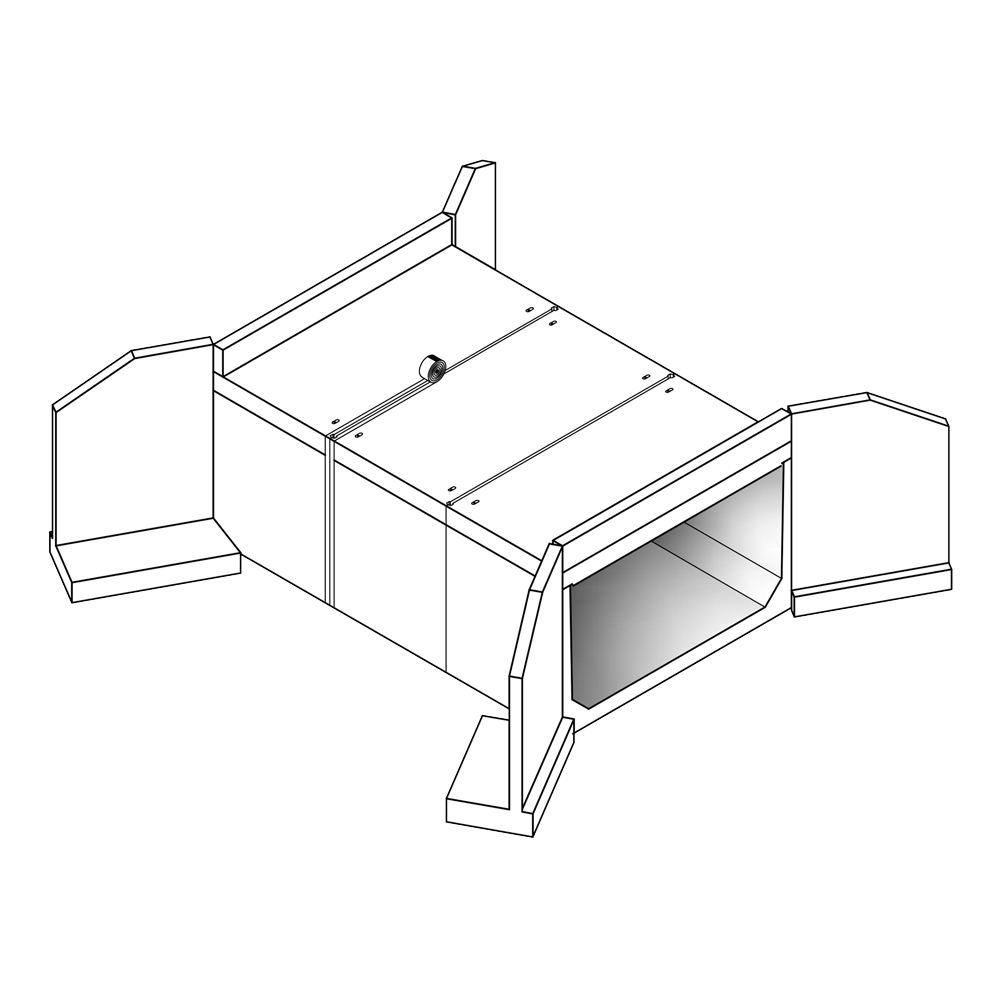

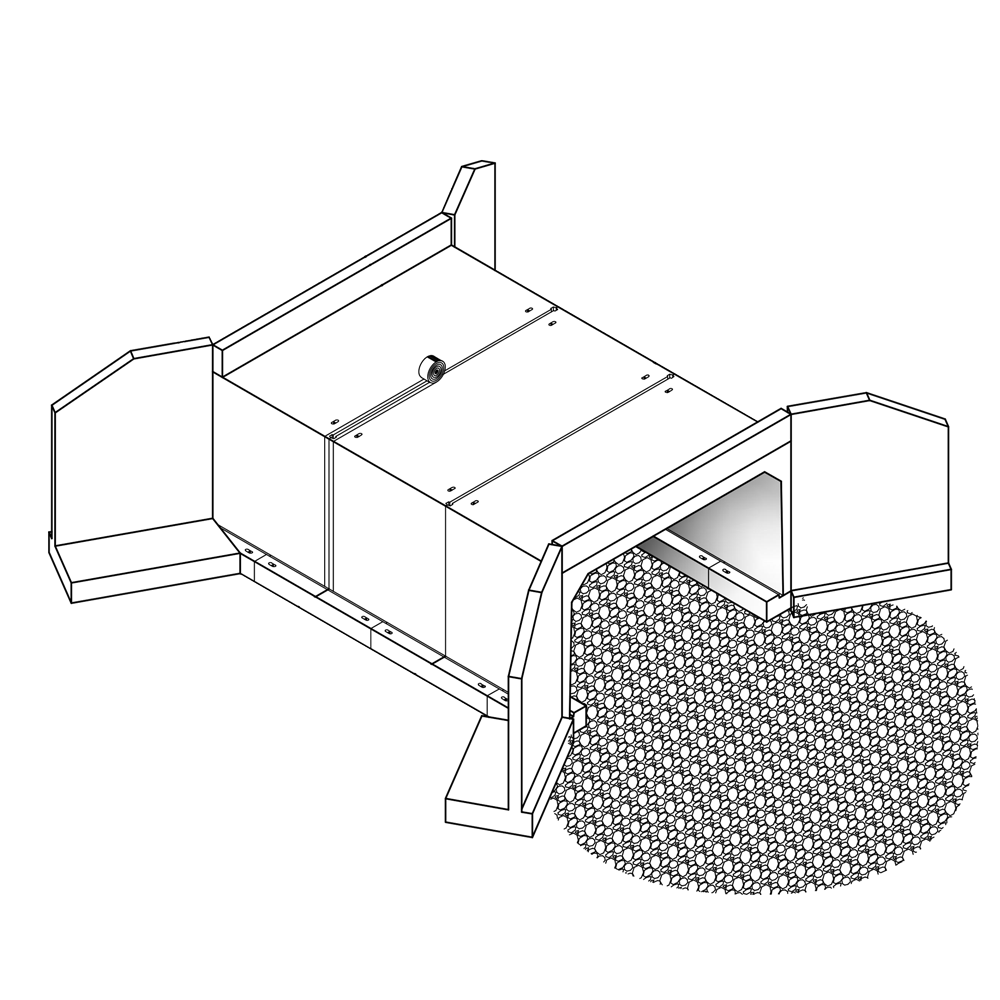

| Split Culvert | Specs |

| Box Culvert Notes |

| Box Culvert Layout |

| Optional Installations |

| Standard Joint Detail |

| Watertight Joint Detail |

| Precast Concrete Bridges | Spec Sheets |

| 3-Sided Bridge | Specs |

| 3-Sided Inverted Bridge | Specs |

| 3-Sided Skewed Bridge | Specs |

| 3-Sided Split Culvert | Specs |

| 3-Sided Bridge Notes |