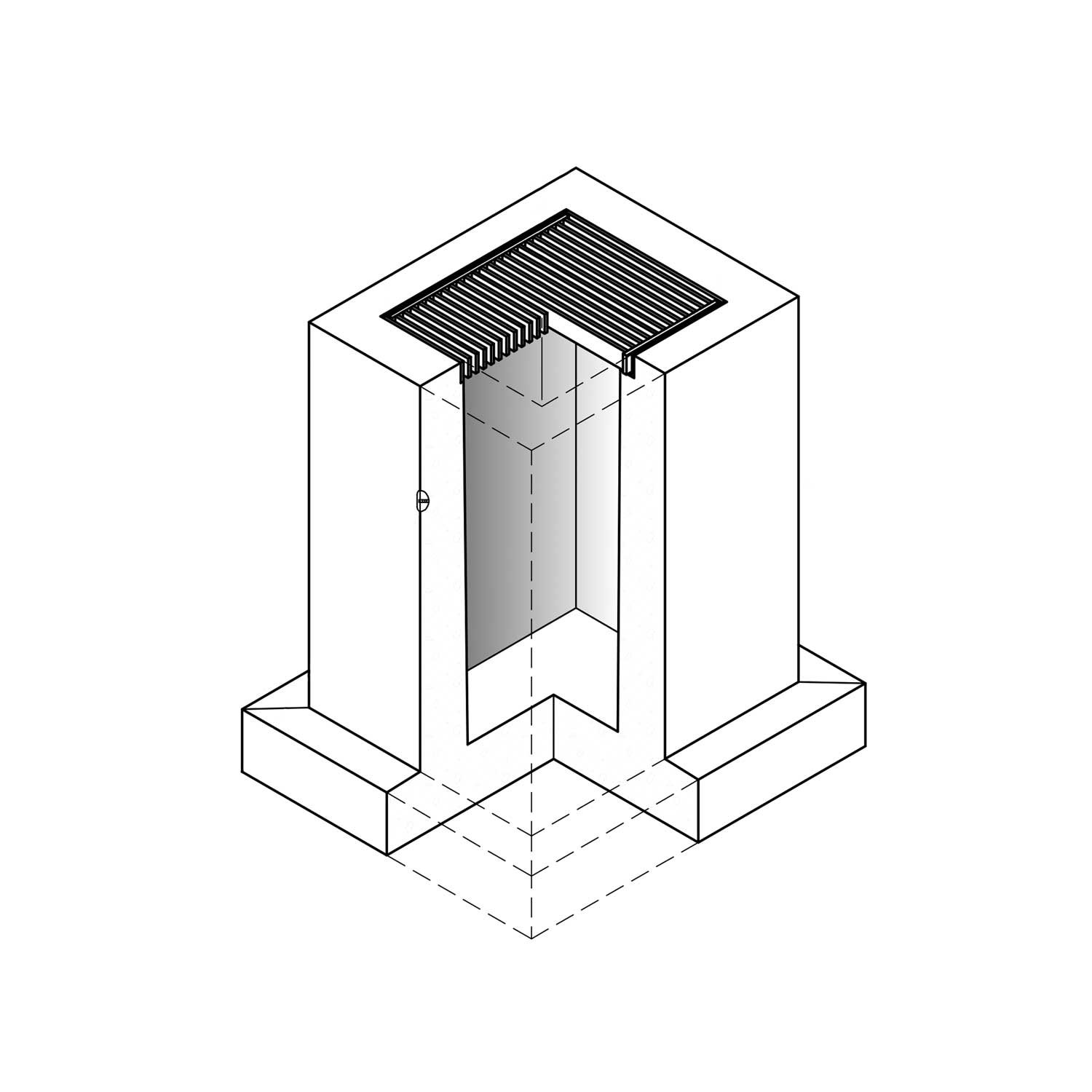

Manholes / Catch Basins

| Manholes | Spec Sheets |

| 24″ Manhole - Mono Base | Specs |

| 48″ Drywell with Eccentric Cone | Specs |

| 48″ Drywell with Flat Top | Specs |

| 48″ Manhole Slope Inlet | Specs |

| 48″ Manhole with Eccentric Cone | Specs |

| 48″ Manhole with Flat Top | Specs |

| 60″ Type 1 Manhole with Eccentric Cone | Specs |

| 60" Type 3 Manhole with Flat Top | Specs |

| 72" Type 1 Manhole with Eccentric Cone | Specs |

| 72" Type 3 Manhole with Flat Top | Specs |

| 84″ Manhole with Reducing Slab | Specs |

| 96″ Manhole with Reducing Slab | Specs |

| 120″ Manhole with Flat Top | Specs |

| 120″ Manhole with Reducing Slab | Specs |

| 144″ Manhole with Reducing Slab | Specs |

| Grade Adjustment Rings | Spec Sheets |

| 25″ Grade Adjustment Rings | Specs |

| 30″ Grade Adjustment Rings | Specs |

| 36″ Grade Adjustment Rings | Specs |

| 42″ Grade Adjustment Rings | Specs |

| Manhole Notes |

| Hole Size Data |

| Maximum Hole Size Data |

Precast concrete catch basins provide a ready-to-install method to collect and filter runoff, separate contaminants, and prevent damage from excessive rainfall or snowmelt.

| Catch Basins | Spec Sheets |

| Airport Catch Basin | Specs |

| BPA Catch Basin | Specs |

| City of Salem Type 1 Catch Basin | Specs |

| WSDOT Catch Basins | |

| WSDOT Type 1 | Specs |

| WSDOT Type 1 Inlet | Specs |

| WSDOT Type 1 Curb Inlet | Specs |

| WSDOT Type 1L | Specs |

| WSDOT Type 1L Ditch Inlet | Specs |

| WSDOT Type 1 Counter-Buoyancy Catch Basin | Specs |

| ODOT Catch Basins | |

| ODOT Type 3 | Specs |

| ODOT Type CG2 | Specs |

| ODOT Type CG3 | Specs |

| ODOT Type G2 | Specs |

| ODOT Type G2 Ditch Inlet | Specs |